May 09,2025●By: Wuxi Geomaster Co., Ltd.

Drill pipes are crucial components in the oil and gas drilling industry, and their reliability and durability are essential for the success of any drilling operation. To ensure that drill pipes continue to perform optimally and maintain their integrity over time, proper maintenance and upkeep are paramount. This article outlines the importance of drill pipe maintenance and the key steps involved in extending their service life.

Importance of Drill Pipe Maintenance

Prevents Costly Repairs and Replacements: Regular maintenance can identify and address potential issues before they become serious problems, reducing the need for costly repairs or replacements.

Ensures Safe Operations: Well-maintained drill pipes are less likely to fail during drilling operations, which can lead to dangerous situations and potential accidents.

Improves Efficiency: Drill pipes that are properly maintained are more efficient and reliable, leading to smoother and faster drilling operations.

Key Steps in Drill Pipe Maintenance

Regular Inspections: Conduct regular inspections of drill pipes to check for signs of wear, corrosion, cracks, or other damage. Use non-destructive testing methods such as ultrasonic testing or magnetic particle inspection to detect internal and external flaws.

Cleaning and Coating: Keep drill pipes clean by removing drilling mud, cuttings, and other debris that can accumulate on their surfaces. Apply a protective coating to the exterior of the pipes to prevent corrosion and wear.

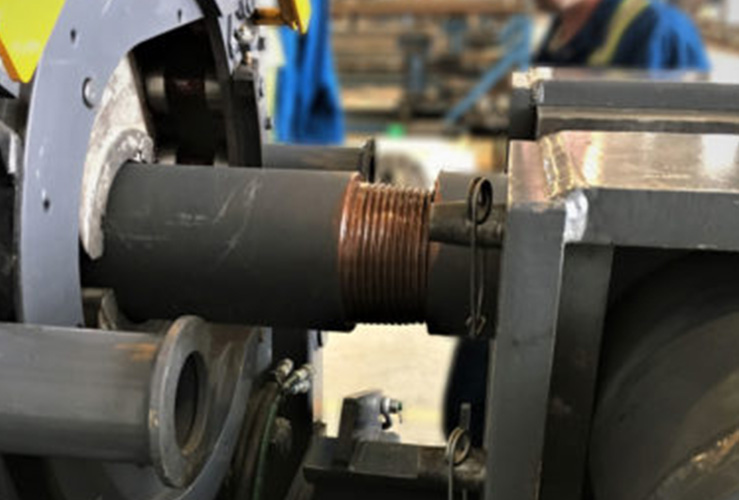

Thread Inspection and Replacement: Inspect the threads on the ends of the drill pipes regularly for wear and damage. Replace worn or damaged threads promptly to ensure proper connections and prevent leaks.

Storage and Handling: Store drill pipes in a dry, clean, and protected environment to prevent exposure to moisture, chemicals, and other potential contaminants. Handle drill pipes carefully to avoid bending, twisting, or dropping them, which can cause damage.

Record Keeping: Maintain detailed records of all maintenance activities, including inspections, repairs, and replacements. This information can help identify patterns and trends in drill pipe failures, allowing for proactive measures to be taken to prevent future issues.

Proper drill pipe maintenance is essential for ensuring the reliability, durability, and safety of drilling operations. By following the key steps outlined above, oil and gas companies can extend the service life of their drill pipes, reduce operational costs, and improve overall efficiency. Regular inspections, cleaning, coating, thread inspection, proper storage and handling, and record keeping are all critical components of a comprehensive drill pipe maintenance program. By prioritizing maintenance, companies can optimize their drilling operations and maximize the return on their investment in drill pipe technology.

Horizontal directional drilling (HDD) machines have revolutionized the pipeline laying industry by offering a trenchless method that minimizes disruption to the...

Dec 03,2024/Exhibition News

Drill pipes are crucial components in the oil and gas drilling industry, and their reliability and durability are essential for the success of any drilling oper...

Dec 03,2024/Industry news

The production of drill pipes, essential components in the oil and gas drilling industry, involves a meticulous and multi-faceted process that ensures their dur...

Dec 03,2024/Company News

Global High-quality Drill Pipe Solution Service Provider

+86-195-8045-6679

Jiaye Financial Center, Taihu Street, Economic Development Zone, Wuxi City, China